1. Introduction to the Industrial Metaverse

1.1 Definition and Conceptual Framework

The Industrial Metaverse can be defined as an interconnected digital environment that combines virtual and augmented reality technologies with physical industrial processes. Its framework encompasses virtual representations of factories, supply chains, and maintenance systems, facilitating real-time data sharing and collaboration across various sectors.

1.2 Historical Context and Evolution

The concept of the metaverse has its roots in early computer simulations and virtual worlds. However, the term gained traction in the late 20th century with the rise of immersive technologies. Over the last two decades, industries have steadily integrated digital tools to enhance productivity, leading to the birth of the Industrial Metaverse as a convergence point for digital twins, IoT (Internet of Things), and advanced analytics.

1.3 Significance in Modern Industry

Today, the Industrial Metaverse is significant because it addresses critical challenges such as increasing operational efficiency, improving workforce skills, and fostering collaboration in an increasingly decentralized production environment. By merging digital and physical worlds, it provides companies with the tools needed to remain competitive.

2. Manufacturing and Production Efficiency

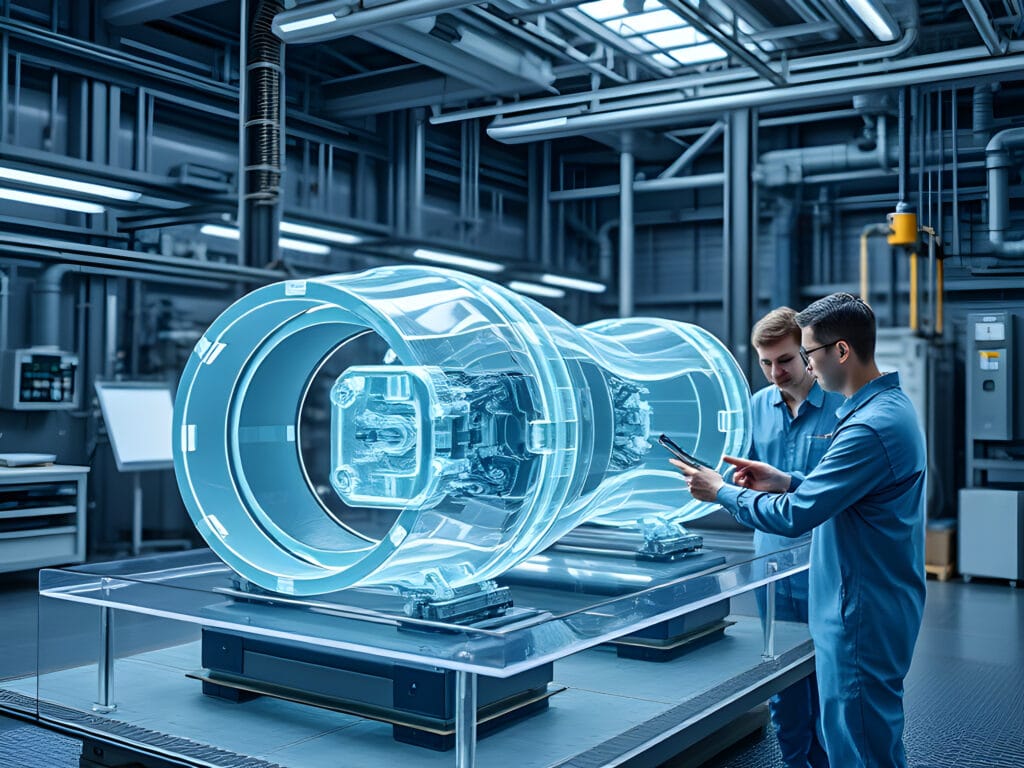

2.1 Virtual Prototyping and Simulation

One of the most impactful applications of the Industrial Metaverse is virtual prototyping. Manufacturers can create detailed 3D models of products to test design principles in a virtual space before investing in physical production. This not only saves resources but also significantly reduces the time from concept to market.

2.2 Real-Time Monitoring and Maintenance

Incorporating IoT sensors allows manufacturers to monitor equipment performance in real time. Data analytics can predict maintenance needs, reducing downtime and maintenance costs. For example, industries that adopt this approach can boost productivity by up to 20%, leading to substantial profitability.

2.3 Collaborative Design and Development

The Industrial Metaverse offers tools for collaborative design, allowing teams across different geographical locations to work together seamlessly. By sharing virtual spaces, they can brainstorm and iterate on designs in real time. This level of collaboration can accelerate innovation and significantly enhance team dynamics.

3. Supply Chain and Logistics Optimization

3.1 Digital Twins for Supply Chain Management

Digital twins are virtual replicas of physical assets, processes, or systems. In supply chain management, they allow companies to simulate supply chain scenarios, identifying potential disruptions and optimizing logistics strategies. By doing so, businesses can anticipate challenges and adapt their operations accordingly.

3.2 Enhanced Inventory Tracking and Management

Integrating real-time data with physical inventories enhances tracking and management. Companies can utilize the Industrial Metaverse to visualize inventory levels, automate replenishment processes, and optimize stock levels based on demand forecasts. This reduces excess inventory costs and enhances cash flow.

3.3 Predictive Analytics for Demand Forecasting

Predictive analytics, powered by data gathered from both the virtual and physical environments, equips businesses to forecast demand accurately. By analyzing past trends and current data, companies can adjust production schedules and inventory strategies, providing a more responsive supply chain.

4. Training and Workforce Development

4.1 Immersive Training Environments

One of the most prominent advantages of the Industrial Metaverse is its ability to create immersive training environments. Employees can engage in interactive experiences that replicate real-world scenarios, enhancing learning outcomes. For example, a manufacturing operator can practice using machinery in a virtual setting before operating it in real life.

4.2 Skill Development through Simulation

Simulations enable employees to refine their skills without the risks associated with live environments. For instance, technicians can troubleshoot equipment issues virtually, gaining proficiency without the cost of downtime or potential errors in the physical world.

4.3 Continuous Learning and Upskilling Opportunities

The dynamic nature of the Industrial Metaverse allows for ongoing education and training programs. Companies can update virtual training modules continuously, enabling employees to stay current with industry standards and technological advancements, fostering a culture of continuous improvement.

5. Environmental Sustainability and Safety Improvements

5.1 Resource Management and Waste Reduction

The Industrial Metaverse can help industries manage resources more effectively, leading to waste reduction. By simulating production processes, companies can pinpoint inefficiencies and develop strategies to minimize waste. This not only saves costs but also contributes to a more sustainable operation.

5.2 Enhanced Safety Protocols and Risk Assessment

The metaverse provides a platform for companies to assess safety protocols and identify potential hazards in a controlled virtual environment. By recreating work conditions, organizations can train employees on safety measures, ultimately leading to fewer workplace accidents.

5.3 Monitoring Environmental Impact and Compliance

Real-time data analytics within the Industrial Metaverse enables companies to monitor their environmental impact continuously. This data can be essential for ensuring compliance with regulations and demonstrating environmental responsibility, which is increasingly important to stakeholders.

6. Conclusion

6.1 Recap of Key Insights

The Industrial Metaverse presents a myriad of opportunities for enhancing efficiency, optimizing supply chains, improving workforce development, and bolstering sustainability efforts. Its ability to integrate virtual and physical environments allows industries to tackle challenges in novel ways.

6.2 Future Prospects of the Industrial Metaverse

As technology continues to evolve, the capabilities of the Industrial Metaverse will expand, offering even more innovative solutions to address complex industrial challenges. Industries that embrace this shift will likely lead in market competitiveness.

6.3 Calls to Action for Industry Leaders

Industry leaders are encouraged to explore the potential of the Industrial Metaverse in their operations. By investing in technology, fostering a culture of innovation, and prioritizing workforce development, they can position themselves for future success.

7. Frequently Asked Questions (FAQs)

7.1 What industries can benefit from the Industrial Metaverse?

Industries such as manufacturing, logistics, healthcare, and construction can all benefit from the Industrial Metaverse by improving efficiencies, enhancing training, and driving innovation.

7.2 How does the Industrial Metaverse impact employment?

While there is concern about job displacement, the Industrial Metaverse also creates new roles focused on technology management, analytics, and advanced manufacturing, necessitating a shift in workforce skills.

7.3 What are the primary challenges in adopting the Industrial Metaverse?

Challenges include the high initial implementation cost, data security concerns, and the need for employee training. However, the potential long-term benefits often outweigh these barriers to entry.

I am really impressed with your writing abilities as smartly as with the layout to your

weblog. Is that this a paid theme or did you modify it your

self? Either way keep up the nice high quality writing,

it’s rare to peer a great weblog like this one these days.

Beacons AI!

I am extremely inspired along with your writing abilities as smartly as with the structure for your weblog. Is this a paid topic or did you customize it your self? Either way keep up the excellent quality writing, it’s rare to look a great blog like this one today!